Improving Your Forward Vision For Geosteering

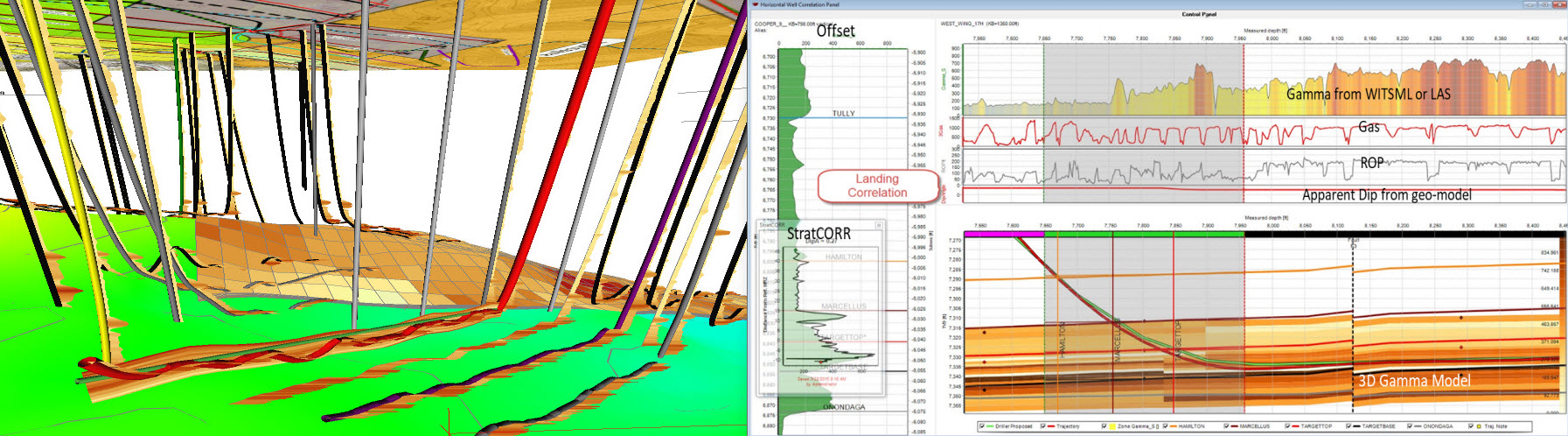

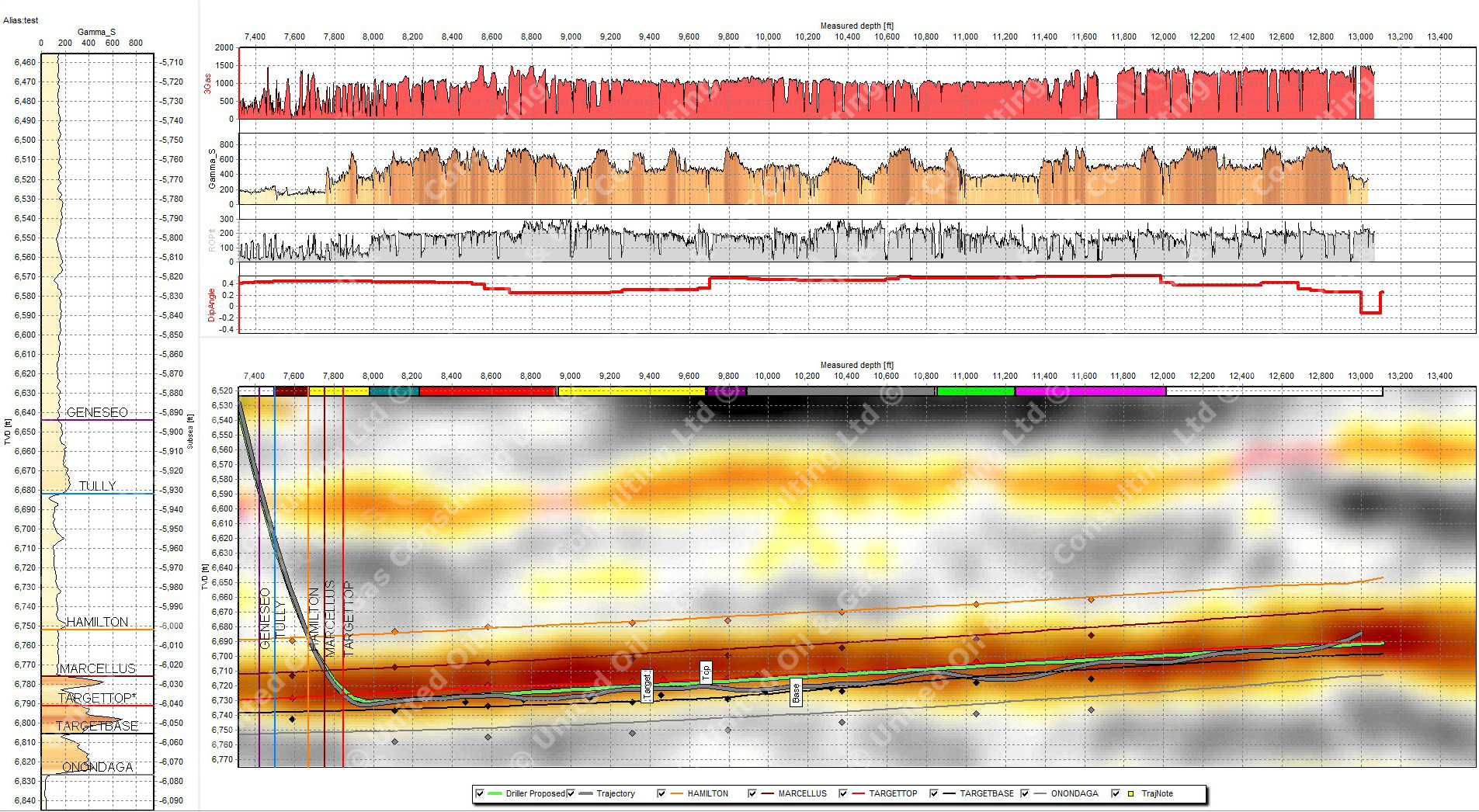

In this series of posts we will discuss the role of SMART4D in geosteering. We have created SMART4D to allow you to dynamically and confidently geosteer toward the target. Our geosteering product provides a real-time solution, making it possible to correlate to the last survey point (how we got here), as well as the latest calculated 3D path to where we are going on the well plans. It increases operational confidence, efficiency and workflow.

Some of the benefits Operations Teams see in SMART4D are:

- Adding accuracy for landings and laterals by a proactive geosteering process

- Reduction of doglegs (DLS) and tortuosity for every well drilled for both Landings (16% reduction) and Laterals (36%)

- Faster drilling reducing rig days ranging from 18% to 36%

The geostering process SMART4D uses improves drilling, with better waypoints, and formation accuracy. The wells remain in their engineered sweet spots longer, thus improving well completions.

True 3D modeling of variability in geology is currently underserved by 2D models. 3D workflows should not only be a requirement of pre-drill models for geosteering but demanded since 3D variability is integral to geology and the nature of rock formations we drill. SMART4D addresses several geosteering needs not only in 3D interpretation but team accessibility to the software through networks and the Cloud as well as web-based reporting and rig data automations.

Other geosteering software solutions solve the correlation element with a single vertical well at a time comparison with a TST (True Stratigraphic Section). While TST method is useful, it creates a reactive geosteering process. It forces the geologist to place too many faults due to the software’s inability to handle thickness variations with single offsets. There are lateral variabilities that are not reflected using TST.

Other approaches to solving for variability process examines a TVD of the last log segment and looks to itself for matching purposes, filling in colors representing a gamma match. At the end of this process it is still a reactive 2D geosteering process.

Here is a driving analogy: No one drives forward with a rear-view mirror. Why should the drilling process work that way? SMART4D has solved this by re-creating an entire 3D interpretation by automating and optimizing 3D kriging to solve the path forward in about 5 minutes. The 3D kriging algorithm in the learning model with real-time data creates the ability to drill with added confidence.

Through over 20 years of R&D and over a 1000 wells geosteered through SMART4D, the collaborative process is bearing fruit for Operators. WITSML rig data retrieval and real-time web reporting tools and leveraging of cloud based access to the process have added efficiencies and convenience for operations geologists and teams. Clear and powerful real-time panels, map views and 3D visualizations through the web and team communications provide the bridges for directional drillers and drilling teams.