Modelling drainage volume of wells (SRVs) is an important Reservoir Engineering step that can reduce the risk of well placement in low pressure areas associated with legacy vertical and newer horizontal wells and their fracs. For both well planning and geosteering this process is important.

SMART4D allows geosteering that is dynamic and confident in the well placement and targeting within a reservoir. In this post we dig into a couple of the other things we have done with SMART4D and how these benefits oil and gas producers.

Other Reservoir Considerations Beyond Geosteering

Producers can reduce technical and financial risk on well placements due to production (Drainage of Offsetting Verticals, Horizontals and their Frac shadows) by some of the processes that United has developed for pre-drill studies.

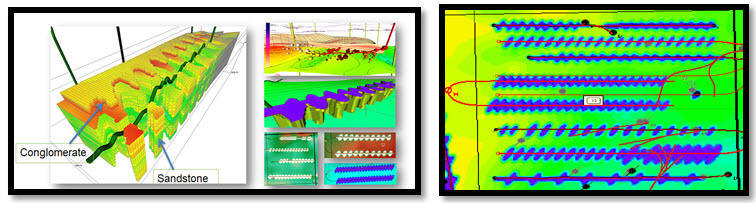

Studies considering a few to a couple of hundred wells by a technology developed by United called Volumetric Sweep Mapping (VSM) models the recoverable volume of HCPV under a Displacement Efficiency (DE) in the wellbore path and fracs. The VSM simulator results have proven to be accurate, faster and more cost effective than full/dynamic simulators.

Volumetric Sweep Mapping®

A volumetric simulation process developed by United in modelling of movable hydrocarbon in the stimulated reservoir volume of fracs and wellbores in Conventional and Unconventional plays. Using the geological framework of the geo-models in SMART4D, the iterative process matches the EURs or cumulative oil volumes to date to the displaceable and recoverable HCPV volume in each frac. In highly detailed voxels about 20’x20’x1’. The downscaled models are from SMART4D and are typically about 10 million cells. This VSM process will be explored further by another paper I’ll be writing on this subject.

Download our VSM Case Study

Please fill out the form below to access our VSM Case Study.